From the Lab

Monday, January 29, 2024

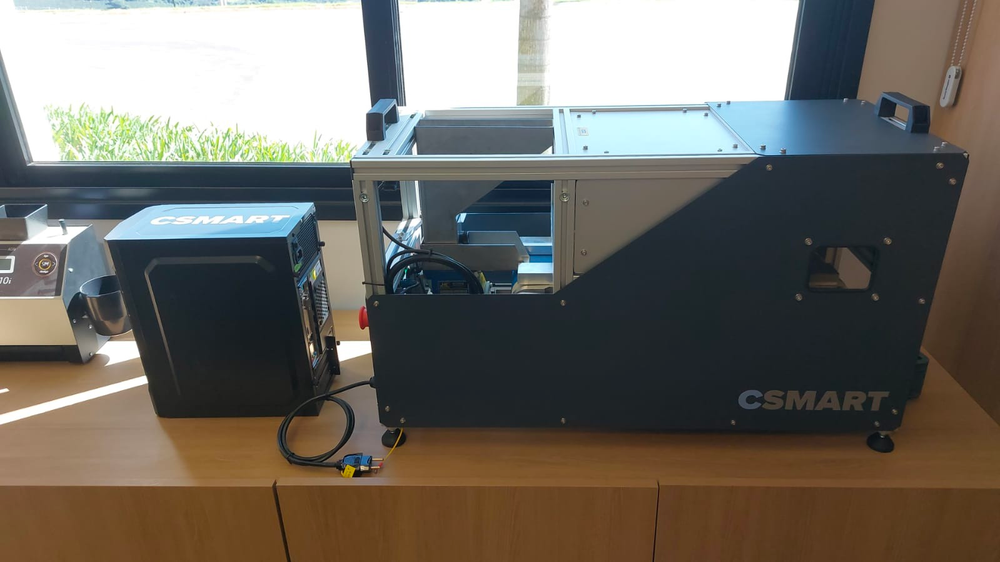

Faster Green Grading with Csmart Digit

Csmart’s Digit is an AI-based, smart green grading machine that we predict will make waves in the coffee industry, increasing transparency and enabling QC personnel to focus on other tasks. We’re excited to share the potential of Digit with you. To get a better sense of what Digit can do, we spoke to Ari Moskowitz, Digital Trading Coordinator at Sucafina.

How does Csmart Digit’s green grading technology work?

Ari: You feed the green coffee into one end, and it moves down a belt. As it moves, a camera identifies and takes a picture of each individual bean as it passes through the belt. It can process a 350g sample in about 4 minutes. After a picture of every bean is captured, Digit then uses an AI model - called a neural-net - to classify each bean as a green grader would. The models learn as you train them, but the models can already identify a full black, partial black, full sour, husk, pod, etc - basically all the identifications that are done in green grading. From that information, you can identify the export grade.

Since each origin and processing method looks different, each origin needs a different model because the color of a good Brazil natural is going to be different from the color of a good Kenyan washed. Once you know the origin, you can run the sample through the model, get the green grading and export grade and have a clear understanding of coffee quality.

What are the major benefits of Digit? Who will use it?

There’s obvious value for exporters and importers, large cooperatives, dry mill operations and warehouses. An efficient and objective grading system allows buyers, sellers and banks to know what is being delivered and shipped. Not every warehouse has a trained green grader with a spare 30 minutes for each arrival, and Digit can do this in a few minutes.

Warehouses and banks can use Digit to mitigate risks of fraud by ensuring the quality of coffee. At the same time, Digit can help arbitrate quality disputes between two parties as a neutral third party, mitigating the cost risk of disputes.

In a production mill that uses Digit to calibrate, Digit’s output allows the mill manager to adjust the machines in real time enabling optimization of the various milling stages and increased efficiency overall.

Digit also enables greater traceability and transparency. Using the Digit, you will have a record of every sample you have green graded. This allows for comparison of green graded samples of the same lot at different points in the supply chain, or green grading results year on year from the same sellers.

Digit will facilitate communication between QC departments at importers, exporters, cooperatives and beyond, and will free up QC professionals to focus on tasks that cannot easily be automated. Digit has the potential to save a lot of time for QC professionals while bolstering their work.

Why is Sucafina involved in this?

Sucafina likes investing in cutting edge technologies within the coffee industry, and we see Csmart’s Digit as an innovator within coffee. We are proud to be a minority investor, along with other industry stakeholders, in Csmart’s technology. Physically, we do a lot of green grading, but we also see value for the industry writ large.

One exciting thing is that Csmart is working to integrate Digit with ProfilePrint and Tastify, two technologies already within our portfolio. With these integrations, you can see your physical green grading alongside your ProfilePrint quality analysis and cupping notes from physical tastings done with Tastify.

What are the latest updates on Digit?

Csmart has created Brazil Arabica and Vietnam Robusta models for Digit, and are working on East Africa Arabica and China Arabica models. We’re looking to ship the first units this year, and we’re looking for early adopters. This is an opportunity for people and businesses that value efficiency and optimization across their QC and production chains to invest in Digit. We’re going to provide direct engagement pathways for adopters and harness their feedback to drive the direction of where this goes next and which models we develop next. I think it’s a really exciting time for people to get involved and help secure their position as an industry innovator with Csmart. As a technology, it’s super exciting and this is the time to get in on the ground floor.

As Ari mentioned, Csmart’s first Digit units will be shipping in the next few months. If you’re interested in learning more or getting involved in early rounds of testing the device, please get in touch with grading@csmart.ai).